When it comes to building digital products, “move fast and break things” may work in consumer tech, but in aviation, healthcare, or finance, breaking things isn’t an option. In strictly regulated environments, a single flaw can cause real safety risks, compliance violations, or operational breakdowns.

As a Product Manager in aviation software, I’ve experienced this reality up close. Leading the development of an Electronic Technical Logbook and related digital solutions, I’ve had to balance innovation with compliance, satisfy diverse stakeholders, and ensure that what looks good in a mockup actually works in the cockpit at 35,000 feet.

This article shares my lessons learned navigating these challenges, with a case study drawn directly from our journey.

The Landscape: Why Aviation Is So Complex

Aviation is one of the most heavily regulated industries in the world. Products must be certified, validated, and tested in real operations before they can be adopted. The challenges are enormous:

- Inaccurate or inconsistent data can compromise safety.

- Fragmented solution landscapes make integration harder.

- Limited offline connectivity puts crews at risk when systems fail mid-flight.

- Inefficient back-office processes can undermine adoption and ROI.

In this environment, you need a product that regulators, pilots, mechanics, and airlines all trust.

Our Mission: Best-in-Class Aviation Mobile Experience

Our Mission: Best-in-Class Aviation Mobile Experience

From the start, our north star was clear:

- Platform agnostic: works across devices and ecosystems.

- Intuitive and easy to learn: pilots and mechanics don’t have time for clunky UIs.

- Offline capable: essential when there’s no Wi-Fi in the sky.

We set out to combine digitalization, technology, and user experience to create products that truly maximize value. But in aviation, “value” is measured in different terms, it’s not just features, but safety, compliance, and efficiency under strict regulation.

The Stakeholder Eclipse: Finding Consensus

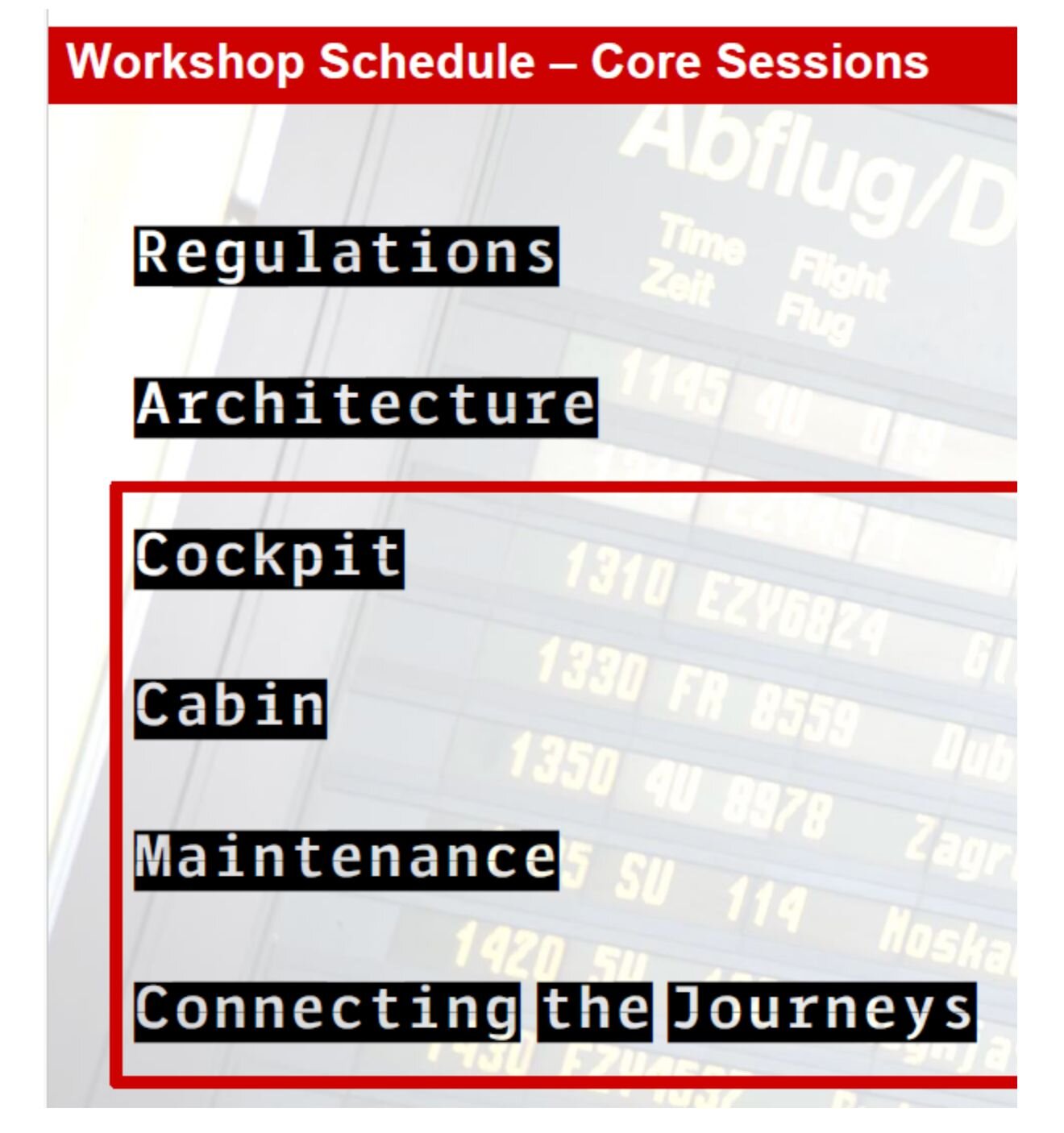

One of the biggest challenges in regulated environments is alignment. At the start of our project, we worked with seven airlines (later ten). Each had its own processes, regulations, and priorities.

Getting everyone to agree felt like aligning planets.

We ran customer workshops where end-users (pilots, cabin crew, mechanics) participated in topic-focused sessions. Their time was expensive and scarce, but absolutely critical.

Challenges included:

- Scarcity of end-user availability.

- The cost of consensus, when every airline wanted different outcomes.

- Risk of design by committee without clear decision frameworks.

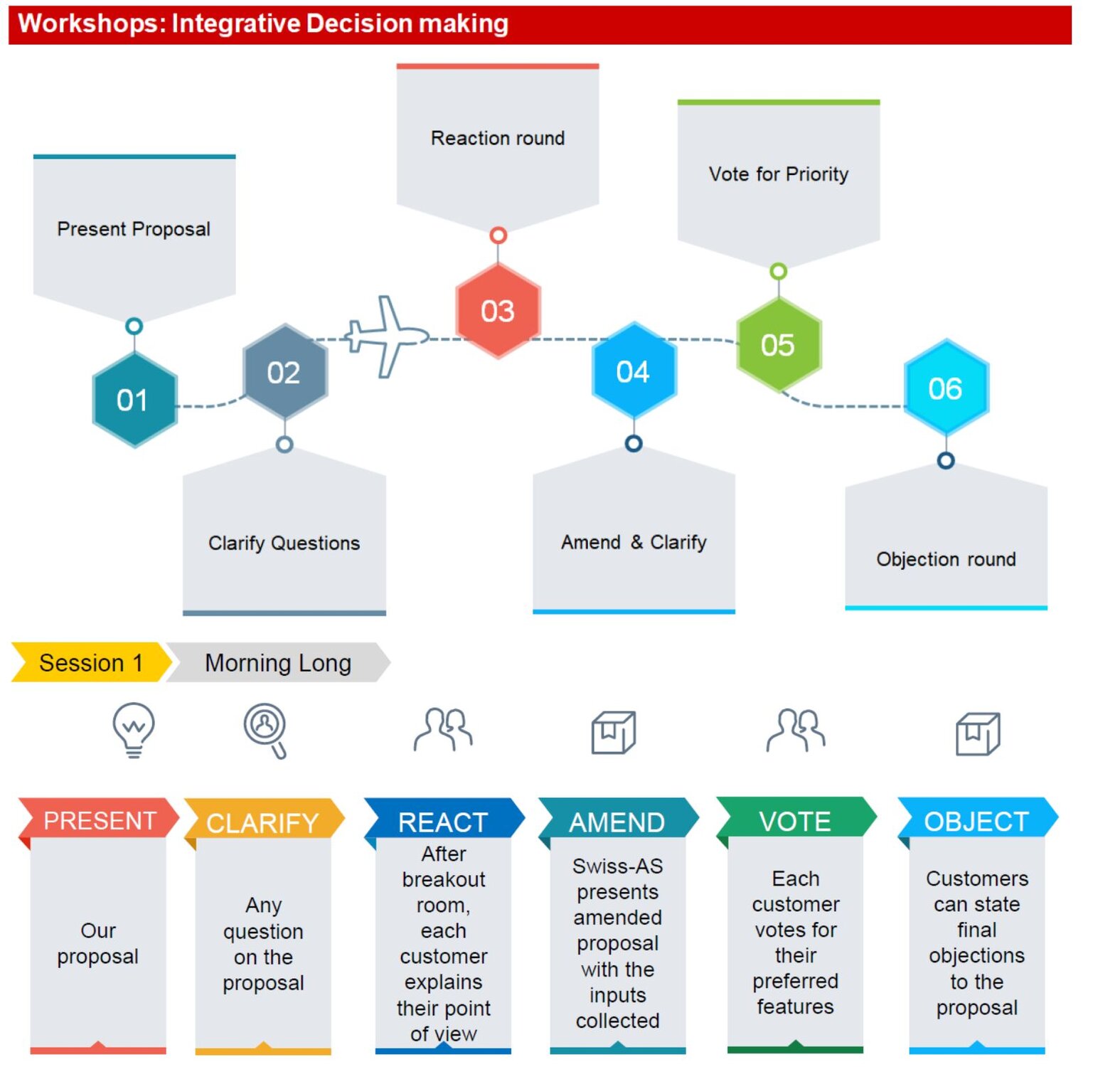

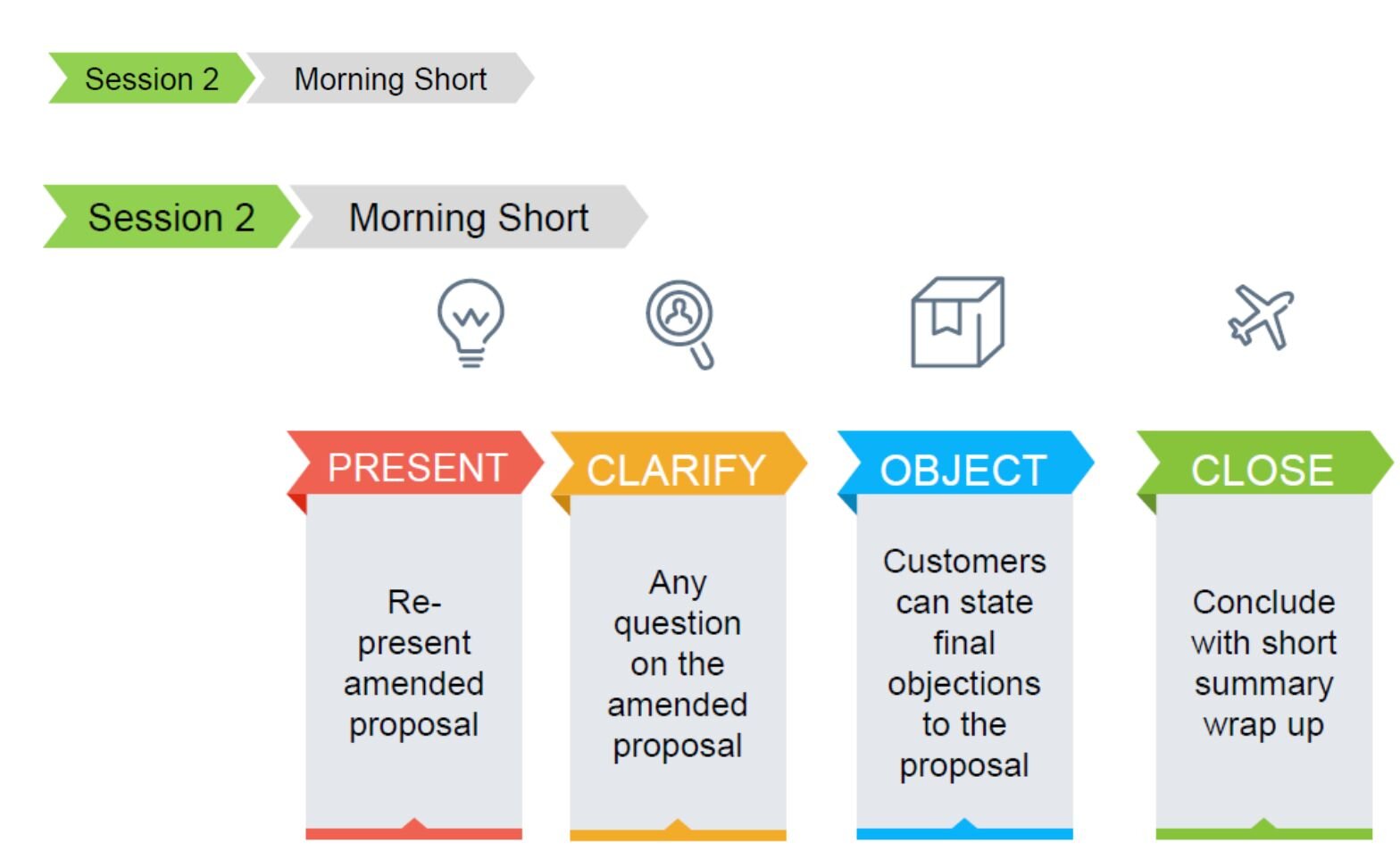

To overcome this, we applied the Integrative Decision-Making (IDM) process. IDM gave us a way to:

- Surface tensions so every airline could raise concerns openly.

- Test proposals quickly, moving forward unless there was clear harm.

- Avoid endless debates and maintain momentum without forcing unanimity.

This structured decision-making was vital in moving from endless “what-ifs” to actionable outcomes that worked across diverse stakeholders.

The Internal Challenges: New Field, New Team

Externally, aligning airlines and regulators was tough. Internally, we faced our own steep climb:

- We were moving from Aircraft Maintenance Engineering into Flight Operations, a new business field with limited company knowledge.

- We adopted a new technology stack (Flutter for mobile, offline-first architecture).

- We were a new agile team, motivated, but untested.

- And of course, COVID was in full swing: workshops had to be performed online, user validation was delayed, and Miro became our cockpit.

Validation in aviation doesn’t happen in a lab. It happens in an aircraft cockpit, with real rews, under real operational conditions. That raised the stakes of every design decision.

Lessons Learned: Avoiding Late Surprises

Along the way, we accumulated plenty of “fail tales.” Some were costly, others funny in hindsight, but all of them taught us valuable lessons:

- You can’t validate too early. Waiting until cockpit testing to discover issues is too late. Build in validation cycles from the start.

- Consensus is fragile. Clear rules and structured facilitation (like IDM) are essential to avoid deadlocks.

- Scope creep is deadly. In regulated environments, every extra feature multiplies the certification and testing burden.

- Technology ≠ Value. A shiny new tech stack won’t save you if the product doesn’t solve operational pain points.

- Iteration must be extended. In regulated spaces, iteration goes beyond agile sprints, it includes parallel runs, paper backups, and regulator touchpoints.

We learned that the biggest risks come when issues are uncovered too late in the process, during cockpit validation instead of earlier workshops and simulations. By then, the cost of fixing them multiplies, both in time and in credibility. The goal is to avoid that moment entirely.

Real Case Study Snapshot: The Parallel Run

One of the turning points in our journey was the parallel run. Pilots were required to use both the new electronic logbook and the traditional paper logbook simultaneously.

This was a regulatory necessity. It gave everyone confidence that the system could work in real-world conditions without risking compliance or safety.

The outcome? We uncovered issues early, validated assumptions under pressure, and gained buy-in from crews and regulators. It slowed us down at first, but accelerated adoption later.

- Operational Efficiency: real-time synchronization between cockpit, cabin, and maintenance teams cut defect reporting and resolution times, directly improving aircraft turnaround time (TAT) and overall schedule reliability.

- Efficiency gains: a considerable drop in manual entry errors, reducing training time and error correction processes time-saving.

- User adoption: close to 90% of staff actively used the system during the final phase of the parallel run. Increasing its chances of success in the productive phase.

- Regulatory Compliance: the system authority validation(aside from NTO letter from EASA). Built-in e-signatures, traceability, and validation improved audit readiness and reduced documentation effort across the fleet.

Gratitude

None of this would have been possible without the amazing team of professionals who contributed with passion and dedication at every stage. My colleagues supported this journey in countless ways, from shaping scope, to iterating designs, to validating inside the cockpit itself.

To each and every one of them: thank you. We are truly proud of what we’ve achieved together.

Closing Thoughts

Building products in highly regulated environments is a marathon, not a sprint. It demands:

- Patience, because compliance slows you down.

- Resilience, because every validation can expose hidden flaws.

- Humility, because end-users and regulators will always find something you missed.

But when it works, when pilots, cabin crew, and mechanics seamlessly adopt your product, you realize that the rigor of regulation doesn’t kill innovation. It sharpens it.

And that is the real lesson: Innovation in regulated industries thrives not despite the rules, but because of them.

Keep reading

Product managers' role in making AI/ML systems more relevant

Designing enforcement as user experience: A case study in PAYG lending

Building products in Africa: Lessons from PMs working on the continent

Behind the seamless OpenTab: How a simple ordering feature turned into a scalable payments system